Blog

The Legacy of Innovation – 3M™ Glass Bubbles

3M™ Glass Bubbles and Their Impact Across Industries

Discover the legacy of 3M™ Glass Bubbles, their innovative origins, and their transformative impact across industries worldwide.

Have you ever wondered how lightweight materials drive innovation across industries? From aerospace to consumer products, 3M™ Glass Bubbles have been a game-changer. Invented by Warren Beck in the 1940s, these hollow microspheres have paved the way for groundbreaking advancements. This article explores the "3M™ Glass Bubbles legacy," its origins, and how it continues to transform the modern world.

Table of Contents:

Related 3M™ Glass Bubbles Articles

Evaluating the Impact of 3M™ Glass Bubbles on Solar Heat Reflection

Increasing Time Until Condensation: Advanced Applications of 3M™ Glass Bubbles (Part 2)

The Legacy of Innovation – 3M™ Glass Bubbles

The Origins of 3M™ Glass Bubbles: Warren Beck’s Vision

Warren Beck, a 3M scientist, revolutionized material science when he identified the potential of hollow microspheres during his work on reflective road signs. This discovery led to the creation of 3M Glass Bubbles—lightweight, durable spheres made of soda-lime-borosilicate glass. Beck's innovation set a foundation for diverse industrial applications, highlighting 3M's commitment to innovation.

Warren Beck - Former 3M Corporate Scientist

Applications Across Diverse Industries

Aerospace and Automotive

3M™ Glass Bubbles have significantly impacted aerospace and automotive industries:

- Weight Reduction: These microspheres reduce vehicle and aircraft weight, enhancing fuel efficiency and lowering carbon emissions.

- Thermal and Acoustic Insulation: They improve passenger comfort by minimizing heat transfer and sound vibrations.

- Structural Safety: Lightweight yet strong, they contribute to crash-resistant designs without compromising integrity.

Oil and Gas

Challenging environments benefit from the unique properties of 3M™ Glass Bubbles:

- Drilling and Cementing: These microspheres reduce the density of drilling fluids and oil well cements, ensuring safety and efficiency.

- Pipeline Insulation: Their low thermal conductivity enhances the energy efficiency of underwater pipelines.

- Deep-Sea Buoyancy: Glass Bubbles provide buoyancy to underwater equipment, critical for deep-sea exploration.

Construction and Building Materials

In construction, 3M™ Glass Bubbles offer a balance of strength and efficiency:

- Lightweight Concrete: They reduce structural loads, enabling sustainable high-rise construction.

- Enhanced Paints and Coatings: From scrubbable walls to anti-condensation paints, these bubbles improve material performance and aesthetics.

- Efficient Sealants: Glass Bubbles make spackling compounds easier to sand, delivering smooth finishes.

Innovative Properties Driving Performance

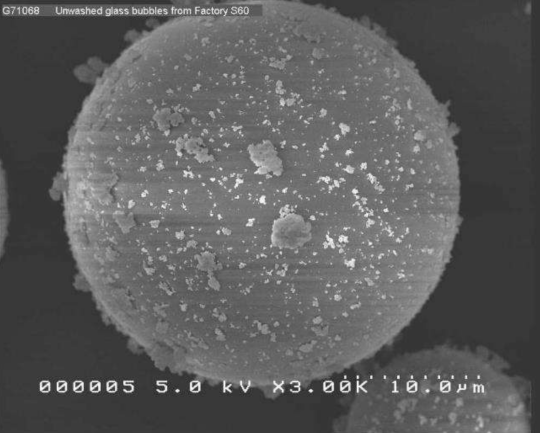

3M™ Glass Bubbles - S60 (microscope)

The unique properties of 3M™ Glass Bubbles make them indispensable:

Lightweight Composition: 20 times lighter than conventional fillers, reducing material weight while maintaining strength.

Thermal Stability: They resist chemical degradation and extreme temperatures, ensuring long-lasting performance.

Cost Efficiency: By reducing resin demand, they lower production costs and enhance material flow.

Warren Beck holds two 3M technologies he worked on - glass beads and glass bubbles

Conclusion

From Warren Beck's groundbreaking discovery to their transformative applications, the "3M™ Glass Bubbles legacy" demonstrates the power of innovation. These tiny yet powerful spheres continue to shape industries, offering solutions for a sustainable, efficient future.

Read the original article here.

Transforme your ideas into reality!

You might also be interested in...

Increasing Time Until Condensation: Advanced Applications of 3M™ Glass Bubbles (Part 2)

You might also be interested in...