Blog

Enhancing Wall Fillers with 3M™ Glass Bubbles

Achieve superior quality in lightweight compounds and other wall filler applications.

Discover how 3M™ Glass Bubbles can enhance wall filler performance by reducing shrinkage, cracking, and sagging while improving workability and sandability.

In the world of construction and home improvement, wall fillers play a crucial role in achieving smooth and durable finishes. Traditional fillers often face challenges like shrinkage, cracking, and high labor costs. However, the incorporation of 3M™ Glass Bubbles in wall fillers can significantly enhance product performance, providing numerous advantages that benefit both applicators and end-users.

Table of Contents:

Related 3M™ Glass Bubbles Articles

Packaging and Handling Options of 3M™ Glass Bubbles

The Technology Behind Anti-Condensation Paints

Mastering the Metering and Mixing of 3M™ Glass Bubbles

Benefits of 3M™ Glass Bubbles in Wall Fillers

Incorporating 3M™ Glass Bubbles into wall filler formulations provides a range of benefits that enhance the overall performance and application process.

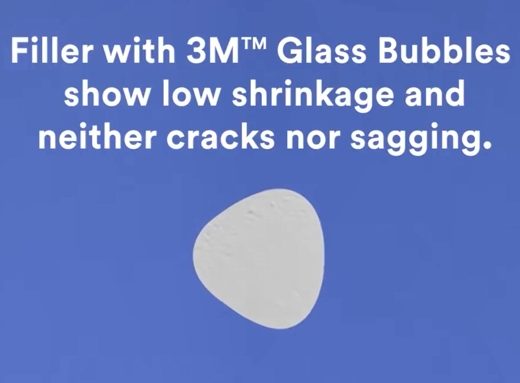

No Shrinkage

3M™ Glass Bubbles help eliminate shrinkage, ensuring a stable and consistent finish that maintains itsintegrity over time.

No Cracks

The use of 3M™ Glass microspheres, prevents cracking, even under stress, providing a more durable and long-lasting finish.

Low Density

3M™ Glass Bubbles contribute to a lower density filler, making the product lighter and easier to handle without compromising performance.

Low Sag

These microspheres reduce sagging, allowing for smoother application and better vertical hold.

Enhanced Workability

The smooth, spherical shape of 3M™ Glass Bubbles incorporated into a filer improves the workability, making it easier to apply and manipulate.

Improved Sandability

Fillers containing 3M™ Glass Bubbles are easier to sand, resulting in a finer finish with less effort.

Nail and Screw Durability

The enhanced durability ensures that nails and screws do not cause cracks in the filler, maintaining a smooth and unblemished surface.

Labor Cost Savings

The ease of application and improved performance lead to significant labor cost savings,making projects more efficient and cost-effective.

Recommended Microspheres

For optimal results in wall fillers, the following 3M™ Glass Bubbles are recommended:

K1: Ideal for low-density applications.

K15: Provides a balance between strength and lightweight properties.

K20: Offers high strength and durability.

Request the Full Guide

Are you interested in taking your wall filler formulations to the next level with the integration of 3M™ Glass Bubbles? For a detailed understanding of how 3M™ Glass Bubbles can revolutionize your wall filler formulations and to access the specific starting formulation used, request the comprehensive guide by filling out the form below. This document provides all the information needed to help you optimize your wall filler effectively.

Conclusion

Integrating 3M™ Glass Bubbles into wall fillers offers numerous advantages, from preventing shrinkage and cracks to enhancing workability and reducing labor costs. These benefits ensure a high-quality, durable, and easy-to-apply product that meets the demands of both professionals and DIY enthusiasts.

Interested in optimizing your wall filler formulations? Request a sample today and take the first step towards creating superior, durable, and easy-to-apply wall fillers with 3M™ Glass Bubbles!