Blog

Packaging and Handling Options of 3M™ Glass Bubbles

Protect the quality of 3M™ Glass Bubbles with the right packaging and careful handling practices.

Learn how proper packaging and handling techniques for 3M™ Glass Bubbles can maintain their quality, ensuring optimal performance in your applications.

3M™ Glass Bubbles are innovative, high-strength, low-density hollow microspheres widely used in various industries to reduce weight, improve insulation, and enhance durability. Given their delicate structure, proper packaging and handling are crucial to ensuring they arrive at their destination intact and ready for use. In this guide, we’ll explore the different packaging options available for 3M™ Glass Bubbles and provide best practices for handling them to maintain their quality during transit and storage.

Table of Contents:

Related 3M™ Ceramic Microspheres Articles

Packaging and Handling Options of 3M™ Glass Bubbles

Boosting Anti-Condensation Paints with 3M™ Glass Bubbles

The Technology Behind Anti-Condensation Paints (Part 1)

Introduction to 3M™ Glass Bubbles

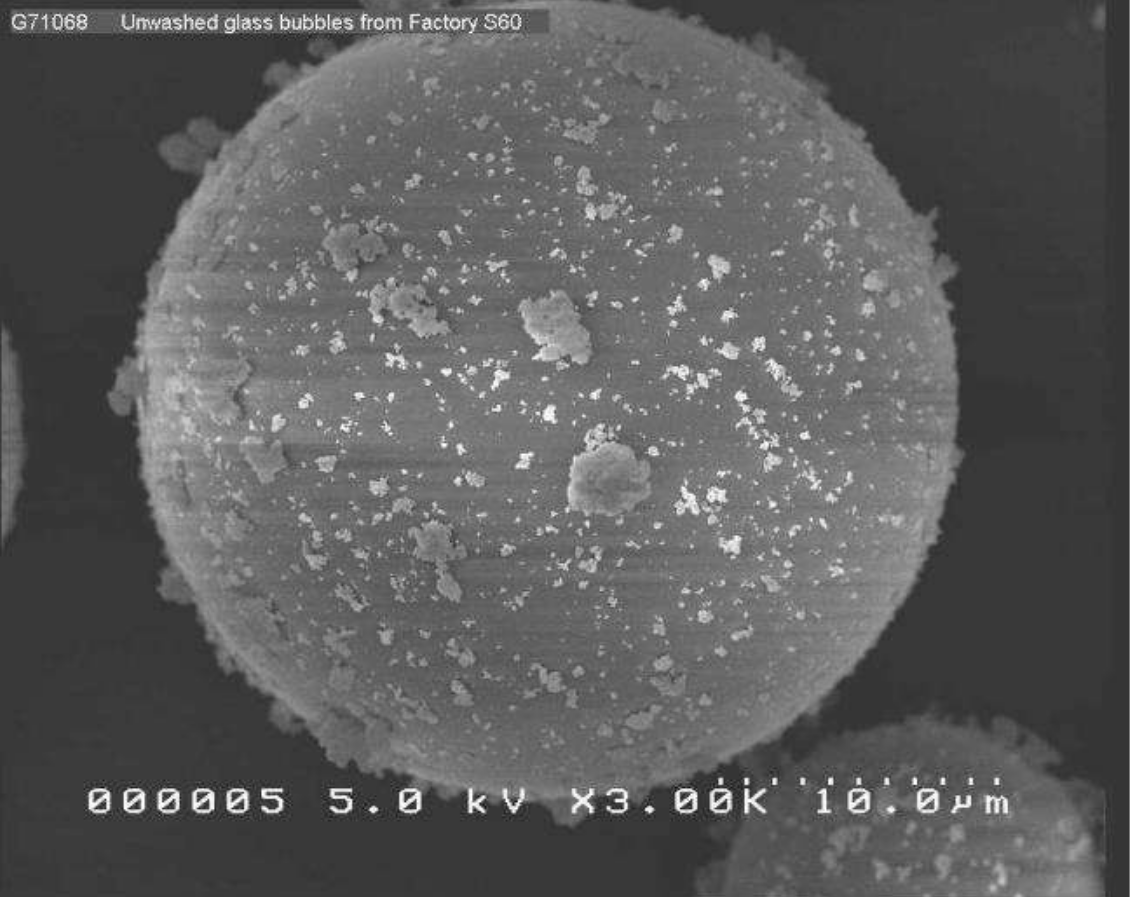

3M™ Glass Bubbles are a versatile material used in industries ranging from automotive to construction due to their unique properties, such as low density and high strength-to-weight ratio. These hollow microspheres are made from chemically stable glass and are ideal for applications requiring lightweight, high-performance materials. However, their hollow structure makes them susceptible to breakage if not handled correctly, emphasizing the importance of proper packaging and handling.

3M™ Glass Bubbles - S60 (microscope)

Packaging Options for 3M™ Glass Bubbles

Small Boxes

Small boxes are ideal for customers who require a limited amount of 3M™ Glass Bubbles for specialized applications or testing. These boxes offer a convenient and manageable solution for smaller-scale operations. The compact size ensures easy storage and handling while protecting the integrity of the glass bubbles.

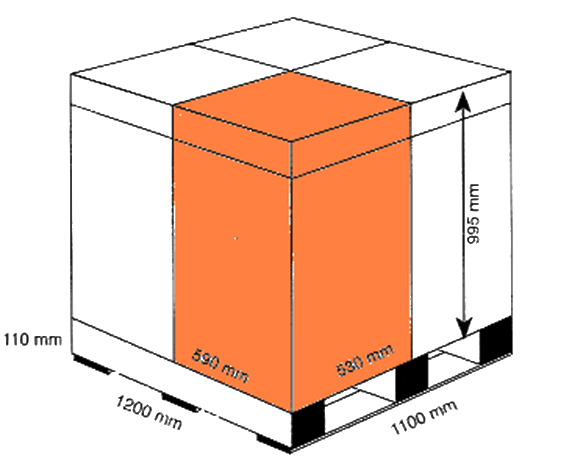

Larger Boxes

For customers needing a higher volume of 3M™ Glass Bubbles, larger boxes provide a more substantial packaging option. These boxes are designed to accommodate a greater quantity while still offering protection against damage during transit. Larger boxes are suitable for medium-scale operations where space and handling capabilities can supportthis packaging size.

Comparison of particle packing efficiency with and without 3M™ Ceramic Microspheres.

High hardness, low-permeation barrier, enhance the exterior durability of coatings.

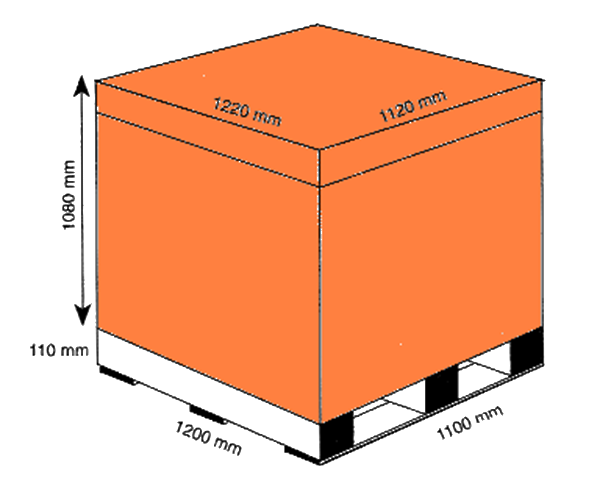

Bulk Bags

Bulk bags offer a solution for large-scale operations where 3M™ Glass Bubbles are used in significant quantities. These bags are double-stacked for efficient storage and transportation, ensuring that large amounts of glass bubbles can be moved and stored with minimal space requirements. Bulk bags are ideal for customers who need to manage a high volume of materials without compromising the bubbles' integrity.

Tankers for On-Site Silo Systems

For customers with on-site silo capabilities, 3M offers tankers designed to deliver glass bubbles directly into storage silos. This option is perfect for large-scale industrial operations where a continuous supply of 3M™ Glass Bubbles is required. Tankers ensure that the bubbles are delivered safely and efficiently, minimizing the risk of damage and maintaining the material's quality from production to application.

3M™ Glass Bubbles Packaging Options

Best Practices for Handling 3M™ Glass Bubbles

Proper handling of 3M™ Glass Bubbles is essential to prevent breakage and ensure they maintain their structural integrity. Here are some tips to handle each packaging type effectively:

Small and Larger Boxes

Handle with care to avoid dropping or stacking them improperly. Ensure that boxes are stored in a dry environment to prevent moisture from affecting the bubbles.

Bulk Bags

When handling bulk bags, use appropriate lifting equipment to avoid puncturing the bags. Double-check that bags are securely fastened during transportation to prevent them from shifting or falling.

Tankers

Ensure that the transfer process from tankers to silos is smooth and controlled. Avoid high-pressure or high-speed transfers that could damage the bubbles.

Request More Information

Enhance the efficiency of your production processes with our optimized packaging and handling solutions for 3M™ Glass Bubbles. By adopting these methods, you preserve the bubbles' low density and structural integrity, resulting in superior performance in your end products. To discover the specific packaging options that can streamline your operations and maintain the quality of your materials, request our comprehensive guide on "Packaging and Handling Options" by filling out the form below.

Conclusion

3M™ Glass Bubbles are a valuable addition to a wide range of products, offering significant benefits in weight reduction, insulation, and durability. By selecting the right packaging and following best handling practices, you can ensure these 3M™ Glass Bubbles arrive intact and ready to enhance your products.

Interested in exploring the potential of 3M™ Glass Bubbles for your applications? Request a sample today and take the first step towards creating superior, high-performance solutions for your applications!

Optimize your paint formulations today!

You might also be interested in...

Increasing Time Until Condensation: Advanced Applications of 3M™ Glass Bubbles (Part 2)

You might also be interested in...