Blog

Enhancing Paints & Coatings with 3M™ Ceramic Microspheres

Discover how 3M™ Ceramic Microspheres improve paints and coatings.

Benefits such as lower viscosity, improved flow, and superior resistance to burnishing and scrubbing, making them ideal for high-performance industrial and architectural coatings.

3M™ Ceramic Microspheres are innovative, uniquely-shaped fillers engineered to provide exceptional benefits in paint and coating formulations. These microspheres help reduce costs, enhance durability, and improve processability, making them indispensable for formulators aiming to achieve superior performance in their products.

Table of Contents:

Related 3M™ Ceramic Microspheres Articles

Unlocking the Potential of Functional Fillers in Waterborne, UV-Curable Coatings

Enhancing Paints & Coatings with 3M™ Ceramic Microspheres

3M™ Glass Bubbles and 3M™ Ceramic Microspheres in the EU Ecolabel Framework

Introduction to 3M™ Ceramic Microspheres

3M™ Ceramic Microspheres are specially designed to meet the needs of paint and coating formulators. Their distinctive shape and particle size distribution enable lower resin demand and reduced viscosities while maintaining high filler loading. These microspheres are suitable for a variety of applications, from residential interiors to industrial structures exposed to harsh environments.

3M™ Ceramic Microspheres

Key Advantages

1. Lower Viscosity and Improved Flow

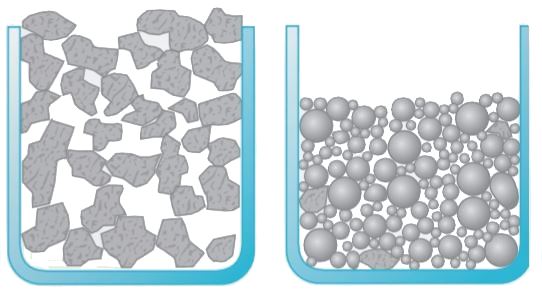

The smooth, spherical shape of 3M™ Ceramic Microspheres allows them to move more freely, similar to ball bearings. This unique property results in lower viscosity and improved flow in paint formulations.

2. Reduced Resin Demand

With their low surface area to volume ratio, 3M™ Ceramic Microspheres help reduce resin demand and increase volume loading capacity. Smaller particles effectively fill voids between larger ones, ensuring high packing density.

3. VOC Management

By enabling higher solids and lower resin demand, 3M™ Ceramic Microspheres assist formulators in meeting stringent VOC (volatile organic compound) regulations, essential for solvent-based paints and coatings.

4. Increased Burnish and Scrub Resistance

The high hardness and smooth shape of 3M™ Ceramic Microspheres contribute to increased burnish resistance. These properties help surfaces maintain their appearance longer, reducing the need for frequent touch-ups or repainting.

Comparison of particle packing efficiency with and without 3M™ Ceramic Microspheres.

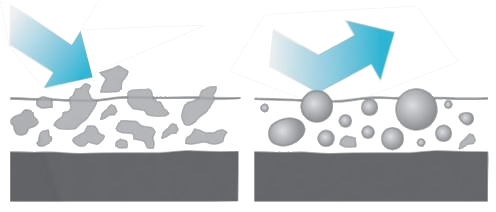

High hardness, low-permeation barrier, enhance the exterior durability of coatings.

5. Gloss Control Enhancement

Incorporating higher levels of 3M™ Ceramic Microspheres can incrementally lower gloss levels without significantly increasing viscosity. This allows formulators to balance gloss and other properties for optimal performance.

6. Improved Exterior Durability

Tight particle packing and high hardness create a durable, low-permeation barrier against weathering, enhancing the exterior durability of coatings.

7. UV Curing Capability

3M™ Ceramic Microspheres are UV transparent up to 250nm, improving productivity and depth of cure for UV-curable coatings by allowing UV energy to penetrate through the coating.

8. Simplified Mixing Process

With high compression strength, 3M™ Ceramic Microspheres can be added during the standard grind process. For optimal dispersion, sand, ball, and roll mills are recommended.

9. Absence of Crystalline Silica

3M™ Ceramic Microspheres are solid particles that contain no detectable crystalline silica, ensuring safety in formulations as verified by x-ray diffraction (XRD) technology.

Request the Application Guide

For an in-depth look at how 3M™ Ceramic Microspheres enhance paint and coating formulations, request the 3M™ Application Guide. This detailed document highlights their applications and benefits, offering all the essential information to understand their impact and value in the paint and coatings industry.

Conclusion

Integrating 3M™ Ceramic Microspheres into paint and coating formulations offers numerous advantages, from reducing resin demand and VOCs to enhancing durability and improving processability. These fillers help create high-performance coatings suitable for various applications, ensuring both aesthetic and functional benefits.

Interested in optimizing your paint and coating formulations? Request a sample today and take the first step towards creating high-performance, durable, and environmentally friendly coatings with 3M™ Ceramic Microspheres!

Optimize your paint formulations today!

You might also be interested in...

Increasing Time Until Condensation: Advanced Applications of 3M™ Glass Bubbles (Part 2)

You might also be interested in...