Blog

Increasing Time Until Condensation: Advanced Applications of 3M™ Glass Bubbles (Part 2)

Lab-validated 3M™ Glass Bubbles S22 performance: up to 45 minutes extended condensation delay

Explore real test results, optimized S22 formulations, and why lower dry-film density extends condensation resistance.

Moisture control remains one of the most persistent challenges in architectural coatings. While introductory (part one) anti-condensation paints offer basic moisture management capabilities, advanced performance requires deeper engineering of thermal conductivity, dry-film density, and CPVC balance.

This second part explores the scientific mechanisms behind condensation delay, using validated laboratory data from 3M™ technical studies and optimized test formulations.

If you haven't read Part 1 yet, start there for the fundamentals of moisture behavior, condensation formation, and the core role of 3M™ Glass Bubbles in thermal stabilization.

Table of Contents:

Related 3M™ Glass Bubbles Articles

Revolutionizing Paint and Coating Industry with 3M™ Glass Bubbles

Packaging and Handling Options of 3M™ Glass Bubbles

The Legacy of Innovation – 3M™ Glass Bubbles

Understanding the Science Behind Condensation Formation

Condensation occurs when surface temperatures fall below the dew point of the surrounding air. In real indoor environments, this often happens on:

- cold interior walls

- corners and junctions with poor air circulation

- basements and semi-underground areas

- bathrooms and kitchens with elevated humidity

The 3M™ technical paper confirms that excessive condensation produces long-term dampness, mold, and degradation of coatings and substrates.

Improving thermal insulation at the paint-film level is therefore a direct method to increase surface temperature and delay condensation formation.

Thermal Conductivity: The Core Principle Behind Anti-Condensation Paints

A coating’s thermal behavior is largely determined by its dry-film thermal conductivity (K-value) and density.

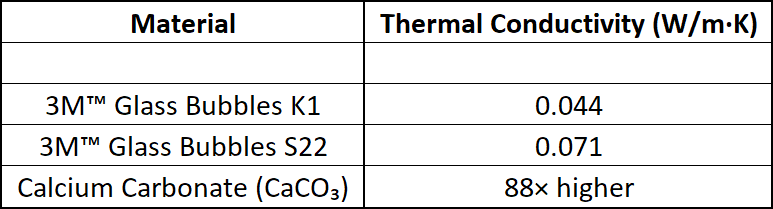

The 3M technical paper presents clear laboratory evidence:

lower K-value → higher surface temperature → longer condensation time.

K-Values of Glass Bubbles vs Standard Fillers

Table 1, 3M Technical Paper

Dry-Film Density: A Critical Performance Driver

The study evaluated multiple commercial anti-condensation paints vs. a standard wall/ceiling paint.

(See Table 2, 3M Technical Paper)

Key findings:

- Standard wall paint: 24 min condensation time

- Commercial “anti-condensation” paints: 20-44 min

- Best-performing commercial paint (#5): 44 min, with dry-film density 0.79 g/cc

- Higher density = lower condensation resistance

The relationship was nearly linear:

Lower dry-film density = longer condensation delay.

This is why 3M™ Glass Bubbles, being hollow, low-density microspheres, are uniquely effective.

Test Method (Scientific Setup)

The condensation test used by 3M is essential for evaluating true performance:

- High-humidity chamber set at 22°C (dew point 19–20°C)

- Cold chamber at 3°C

- Painted aluminum panels placed between the chambers

- Measured parameter: Time until first drop of condensation forms

This method provides repeatable differentiation between paint formulations.

Optimized Anti-Condensation Formulation with 3M™ Glass Bubbles S22

The study developed an optimized lab formulation using S22 Glass Bubbles:

Key properties: (Table 3, 3M Technical Paper)

- Wet density: 0.97 g/cc

- Dry density: 0.95 g/cc

- PVC: 60%

- Film below CPVC: 1.16 ratio

- Glass Bubbles loading: 11 wt% / 50 vol%

- Condensation time: 45 minutes

This value surpasses several market products tested, making it one of the highest-performing anti-condensation paints in the study.

Why S22 Glass Bubbles Deliver Superior Performance

From the technical paper’s conclusions:

Key properties: (Table 3, 3M Technical Paper)

✔Low thermal conductivity (0.071 W/m·K)

Delays heat loss from the paint film.

✔ Low dry-film density

Directly correlates with longer condensation delay.

✔ Formulation below CPVC

Ensures a non-porous, durable film with good scrub and stain resistance.

✔ Absence of CaCO₃

Prevents thermal bridging through highly conductive mineral extenders.

These advantages combine to deliver one of the most effective moisture-control coatings achievable with current raw material technologies.

Key Applications

- High-humidity interiors

- Bathrooms and kitchens

- Basements and semi-subterranean rooms

- Garages, storage areas

- Cold walls prone to condensation risk

- Residential and commercial buildings requiring moisture protection

Request the Technical Paper & Optimized Formula

You can access the full formulation, including component ratios and lab methodology, through our technical request form.

Conclusion

3M™ Glass Bubbles significantly enhance anti-condensation paints by lowering thermal conductivity, reducing dry-film density, and creating durable, closed-film structures.

Interested in engineering high-performance anti-condensation coatings?

Request a sample or formulation consultation today and take the next step toward advanced moisture-resistant coating design.

Optimize your paint formulations today!

You might also be interested in...

Increasing Time Until Condensation: Advanced Applications of 3M™ Glass Bubbles (Part 2)

You might also be interested in...