{{placeholder content=’e3ticml6eV9kY19wb3N0X3RpdGxlfX0=’}}

{{placeholder content=’e3ticml6eV9kY19wb3N0X2V4Y2VycHR9fQ==’}}

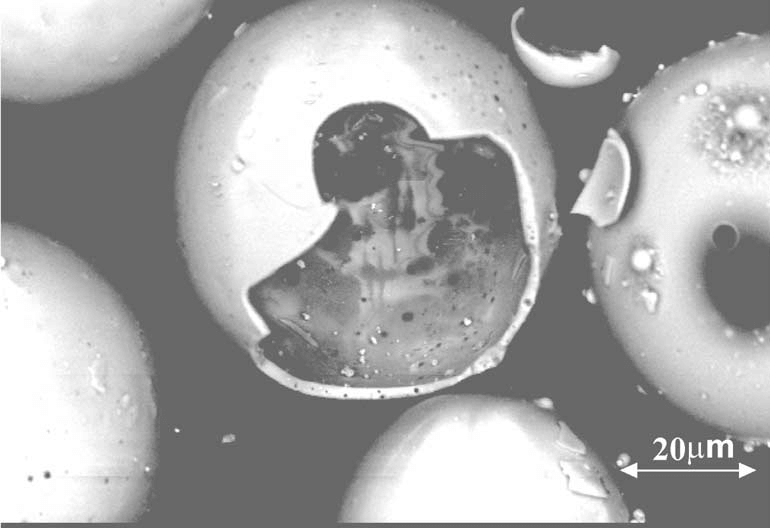

Fig. SEM micrograph of broken cenosphere showing its hollow characteristics and porous walls.

Addressing Urban Noise with Innovative Materials

Noise pollution, a growing concern in both urban and rural societies, impacts the quality of life and health of many individuals. The search for effective sound absorbing materials has led to significant advancements in this field. Among these innovations, hollow ceramic microspheres stand out as a promising solution in sound insulation, offering unique properties to mitigate noise from varioussources like vehicles, aircraft, and machinery.

The Science Behind Sound Absorption

Sound absorption involves the conversion of sound energy into heat, primarily through two mechanisms: flexural vibrations and porosity effects. Porous materials, such as synthetic foam and mineral wool, are traditionally used for their ability to reflect sound within their structure, transforming sound energy into heat. However, hollow ceramic microspheres offer an enhanced approach to sound

insulation.

Fig. Cross-section of impedance tube showing variation of pressure as a function of distance from the specimen.

Innovations in Sound Insulation

Recent studies have shown that enriching coating materials with hollow ceramic microspheres leads to a considerable improvement in sound absorption properties. Here are the keyfindings:

Reduced Mass Density

The mass density of the material decreases by 40% when the volume fraction of cenospheres increases to 70%.

Increased Sound Absorption

The addition of up to 40% volume of cenospheres results in a significant increase in sound absorption.

These findings highlight the potential of hollow ceramic microspheres in creating more effective sound-insulating materials.

Advantages of Hollow Ceramic Microspheres in Sound Insulation

The utilization of hollow ceramic microspheres in sound insulation presents several advantages:

Lightweight Solution

Their low density contributes to lighter construction materials without compromising insulation efficiency.

Enhanced Acoustic Performance

The unique structure of these microspheres increases the sound absorption capability of the materials they are incorporated into.

Paving the Way for Quieter Environments

The incorporation of hollow ceramic microspheres into sound insulation materials represents a significant step forward in addressing noise pollution challenges. Their lightweight nature combined with improved acoustic performance makes them an ideal choice for both urban and rural environments. As research and development in this area continue, hollow ceramic microspheres are set to play a crucial role in creating quieter, more peaceful living spaces.

Find more for Hollow Ceramic Microspheres

{{ brizy_dc_global_blocks position=’bottom’ }}