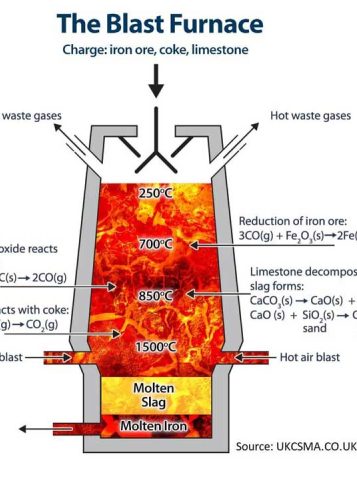

GGBS (Ground granulated blast-furnace Slag)

Utilization in cement and cementitious matrices

In the ever-evolving world of sustainable construction, 3M Glass Bubbles have emerged as a pivotal innovation. These unique materials are redefining the efficiency of roof coatings by significantly boosting their solar reflectance. This article delves into how 3M Glass Bubbles are offering a ground breaking, energy-saving alternative to conventional materials in the building industry.

Traditional cement manufacturing consumes a large quantity of energy and emits high amounts of carbon dioxide due to calcination of limestone and combustion of fossil fuel. Carbon dioxide (CO2) is known as the main heat-trapping gas largely responsible for most of the average global warming over the past several decades. Given its high emissions and critical impact on environment, the cement industry is an obvious field to refer to in order to reduce CO2 emissions.

The combination of GGBS into cementitious mortars production could provide various characteristics during application such as:

- Temperature reduction during concrete hydration in massive structures

- Lessening of the water permeability, porosity and improvement of the cement strength relationship

- Durability in Chloride Attack

- Effect on pH stability

Learn More About GGBS